Our Biosolids treatment project

Our current process

![]() Canberra’s wastewater is separated into liquid and solids as part of the wastewater treatment process. These organic solids are known as biosolids.

Canberra’s wastewater is separated into liquid and solids as part of the wastewater treatment process. These organic solids are known as biosolids.

Biosolids are placed within one of two furnaces, where the intense heat destroys pathogens and contaminants. This creates a product we call Agri-Ash, which retains elements of lime and phosphorus. Agri-Ash is a beneficial soil enhancer used on farmland. On average, we collect Agri-Ash three days per week for distribution to regional farmers.

An opportunity to improve

Both furnaces are approaching the end of their service life and maintenance is becoming increasingly expensive.

Our plan is to replace the old furnaces with an environmentally sustainable, and energy efficient technology to service our growing community over the next 50 years. We have consulted with experts, and industry partners, from across the globe to identify a shortlist of viable treatment alternatives.

How was the solution selected?

After carefully assessing 17 options, five were shortlisted. These shortlisted options would provide a reliable service that continues to protect human health and the environment. They would also help maximise resource recovery by producing energy or providing us with a product that can be re-used (like Agri-Ash).

Our options:

Of the 17 options we carefully assessed, five have been shortlisted:

- Option 1: Fluidised Bed Combustion (FBC)

This option is similar to our existing furnaces (by using intense heat) but is much more efficient and reliable. FBC produces electricity to offset our plant’s onsite use. It also creates an ash like the Agri-Ash we are already producing - Option 2: Anaerobic Digestion (AD)

This option processes the solids from wastewater using anaerobic biological processes. The biosolids produced by this process can be used on farmland. The methane produced can either be converted into electricity or used to dry biosolids. - Option 3: AD plus external biodegradable waste streams

This process is like Option 2, but it is amplified by extra waste streams from local industry. This helps others by taking their waste and creates more electricity from methane. - Option 4: AD plus off-site composting

This process is the same as Option 2, except it includes processing waste off site at a third-party composting facility. This composted product can be used on gardens or farmland. - Option 5: Gasification

This option is like Option 1, but combustion occurs in a low oxygen environment. The product from this process is a biochar which is more beneficial to agriculture than Agri-Ash because of its higher organic content. This process produces electricity to offset our plant’s onsite use.

Options assessment:

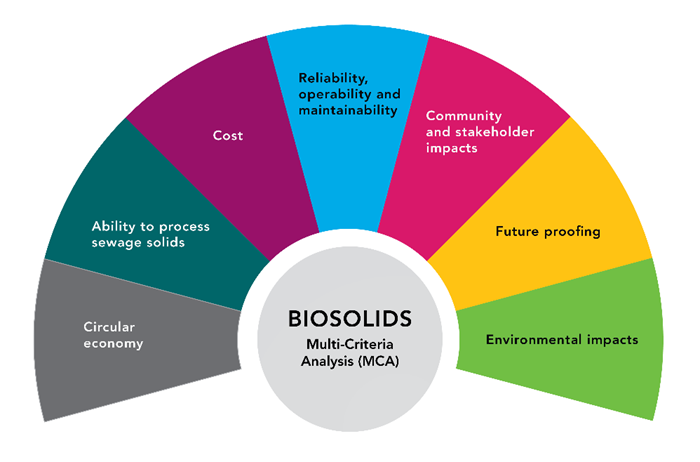

These options went through a robust multi-criteria analysis to make sure we chose the best solution that considered cost, the needs of our community, our environment and factored in circular economy opportunities.

After rigorous assessment of suitable options, high-tech heat treatment, known as Gasification, has been identified as the biosolids treatment solution that will provide the greatest community and environmental outcomes in terms of energy efficiency, enhanced resource recovery opportunities and ability to provide treatment of micro plastics and contaminants of emerging concern. The technology is auto thermal, meaning it needs an initial point of combustion for start-up, and then uses the biosolids as the ongoing fuel source to run. The initial combustion source is flexible, meaning that as the ACT transitions away from use of natural gas, we will not be bound to this energy source.

Gasification was the best performing technology out of all shortlisted options in terms of the following criteria:

- Emissions and climate change mitigation

- Energy recovery

- Truck movements

- Value for money for Icon Water’s customers (to find out how we fund these projects, see our factsheet on infrastructure funding).

- Circular economy benefits

- Flexibility to adapt to future challenges.

How long will it take?

We are hoping to commence construction between 2025-28.

We will be engaging with the community as we progress this important project.

Project timeline