Our Bioreactor project

Our current process

Microorganisms are a critical part of our wastewater treatment process. They convert the nitrogen found within our wastewater into nitrogen gas, minimising the impact on our river ecosystem. Something so vital to our treatment process, and the environment, needs dedicated infrastructure.

An opportunity to modernise

Our secondary treatment process is approaching capacity as Canberra’s population nears the half-million mark. New technologies present an opportunity to enhance performance on a range of measures, whilst also increasing capacity. Our team has investigated different options for upgrading the secondary treatment process in a staged approach to ensure we can service our community through the next 50 years.

Latest news

On 12 May 2025, we submitted an amendment to the approved bioreactor development approval (DA#202341913) to the Environment, Planning and Sustainable Development Directorate (EPSDD).

The application is currently open for public notification from 29 May until 20 June 2025. This gives stakeholders and members of the community another opportunity to provide submissions and participate in these projects.

Click here to view our amendment on the ACT Planning website.

We will continue updating this page as the project progresses.

FAQs

Why is Icon Water upgrading the secondary treatment process at Lower Molonglo Water Quality Control Centre (LMWQCC)?

The LMWQCC has been serving the Canberra community for decades, but with our growing population, certain aspects of the treatment process are reaching their capacity. We have a responsibility to safeguard our environment and continue delivering high-quality wastewater services. To achieve this, we must upgrade or replace key elements of the treatment process.

Stage one of the project focuses on expanding the capacity of the secondary treatment process by introducing a new membrane bioreactor system. In stage two, the existing bioreactors will be upgraded with membrane bioreactor technology. By phasing the project, we can implement the infrastructure gradually, managing costs more effectively while ensuring it scales with the community’s growth.

The contract for the design and construction of stage one has been awarded to a joint venture between Seymour Whyte Constructions and Vinci Construction Grands Projets Australia, who bring extensive experience in the design and construction of membrane bioreactor technology.

When does construction start and how long will it take?

Construction on the secondary treatment upgrade project will occur between 2025 – 2028.

Interested in employment opportunities or becoming a supplier for the project?

We are committed to involving local individuals and companies.

For any procurement information about our bioreactor project, you can contact Seymour Whyte at icon.procurement@seymourwhyte.com.au.

For all other procurement information please contact procurement@iconwater.com.au.

Why is Icon Water submitting another development application?

A development application (DA) was submitted to the Environment, Planning and Sustainable Development Directorate (EPSDD) and approved in 2024, following selection of the bioreactor technology and development of design (DA#202341913).

An amendment to the original DA was submitted to reflect additional specific design developments in April 2025 (DA#202341913) Specifically, we developed the design to reduce and optimise the footprint (area) for the new facilities, as well as allow for the beneficial reuse of materials on site where possible. These changes aim to reduce the impact of the project and provide the best value to the community.

What local community impacts are expected?

During the construction of the new facilities, residents and local community members may notice change in the area particularly those who live along Stockdill Drive, Shepards Lookout walking track users, and potentially residents in nearby suburb of Ginninderry.

Throughout the construction period, Stockdill Drive will experience increased traffic from light vehicles and trucks delivering plant and equipment. The road will be regularly used by construction teams and support vehicles accessing the site.

Shepards Lookout walking trail users may see the construction works as the trail passes LMWQCC however the plant is not visible from the Lookout.

Some noise may be experienced throughout the construction period as a result of ongoing works.

Is there community engagement for this project?

We will be engaging with the community as we progress this important project.

What environmental impacts are expected?

We’ve taken meaningful steps to minimise the impact of the development by optimising and consolidating new infrastructure. As part of the Development Application (DA) amendment process, we obtained an Environmental Significance Opinion (ESO), which concluded that the proposed works are unlikely to result in significant environmental impact. The ESO also recognises that the site is already well established with ongoing operations. The project will incorporate a range of mitigation measures, including:

- Minimising tree removal with work supervised by a qualified arborist.

- Rehabilitating all disturbed areas and replacing trees around the site to enhance overall ecological values.

- Trees near the construction works will be protected with fencing around the boundary of the protection zone.

- Tree replacement will be in accordance with the requirements of the conservator (or approval authority).

- Sediment and erosion control measures.

- Wildlife exclusion measures.

How long will these upgrades continue to serve our growing population?

We regularly assess both plant performance and future population projections to ensure our infrastructure keeps pace with growth. Once complete, the secondary treatment upgrades will increase capacity to support a population of around 660,000 people. Looking ahead, we continue to evaluate network configurations to meet the needs of our expanding community.

How are these upgrades funded?

At Icon Water, we invest in essential infrastructure on behalf of our customers. The water and wastewater bills you pay help fund critical upgrades, ensuring we can continue to deliver reliable services now and into the future. To learn more about how we’re planning for the future and what’s included in the current pricing period (2023–2028), view our factsheet.

Will the project create odour impacts?

The LMWQCC is Canberra’s primary wastewater treatment plant operated by Icon Water. Utility activities at LMWQCC are subject to a range of environmental, health, safety, waste, technical and price regulations. Managing odour associated with treating Canberra’s wastewater is part of what we do everyday. We are regulated to ensure impacts of odour meet requirements of the Environment Protection Act 1997 (ACT) accounting for a specified Environmental Clearance Zone that surrounds the plant. The bioreactor project will see us installing newer equipment, that will allow for increased treatment capacity but is not expected to contribute to any additional odour from the site.

If you notice odour and believe is associated with our operations or assets, we encourage you to talk to us on 02 6248 3111, or you may find this information helpful.

Where can I subscribe to updates?

We value your interest in our project and welcome your feedback. If you’d like to share your thoughts or join our mailing list for updates.

For general enquiries or to make a complaint, feel free to contact us via talktous@iconwater.com.au or call (02) 6248 3111.

How was the solution selected?

Icon Water assessed nine options and identified the risks and benefits of each, from which a shortlist was created to undergo further investigation:

- Option 1: Convert our existing bioreactors into a membrane bioreactor

A membrane bioreactor combines membrane filtration with a biological treatment process. - Option 2: Duplicate the existing process (with updated technology)

For this option, we would construct additional process trains but integrate similar but newer technology. - Option 3: Aerobic Granular Sludge (Nereda ®)

This trademarked process treats wastewater by creating compact sludge granules. - Option 4: Integrated Fixed Film Activated Sludge (IFAS)

The IFAS system consists of tanks filled with small pieces of plastic that create a habitat for microorganisms to attach and grow.

Options assessment:

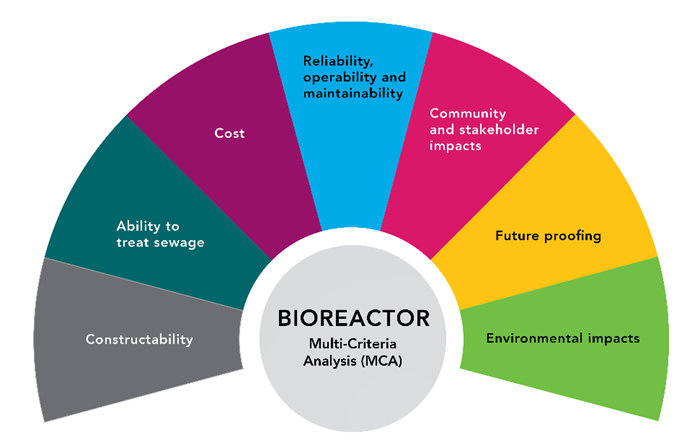

These options went through a robust multi-criteria analysis to make sure we chose the best solution that factored in cost, the needs of our growing community, our environment and ensured our ability to treat wastewater to a high standard.

After rigorous assessment of suitable technologies, it was determined that our new biological treatment should be upgraded to membrane bioreactors, as Stage 1 of the project. Stage 2 will involve converting the existing bioreactor to membrane technology.

The staging of the project will allow for the infrastructure to be installed over time to spread out the cost and ensures it is right sized for the growing population.

Membrane technology stood out as the best option when assessed against the following criteria:

- Treatment process reliability, operability & maintainability

- Environmental impacts

- Community impacts

- Constructability and flexibility to adapt to future challenges

- Value for money for Icon Water’s customers (to find out how we fund these projects, see our factsheet on infrastructure funding).

- Ability to fit into the existing, space limited, site

Full project timeline

Click to enlarge