Bioreactor project

We’re building new bioreactors and supporting infrastructure at the Lower Molonglo Water Quality Control Centre (LMWQCC) to ensure Canberra’s wastewater treatment keeps pace with our growing population and changing climate.

This project will increase capacity and ensure we can continue to safely return treated water to the Molonglo River. It’s about protecting our environment, planning for future demand, and building a system that will serve the community for decades to come.

Latest news | ||

Date | Snapshot | Status |

| 24 February 2026 | A surface miner has been delivered to LMWQCC. This machine will move us into the next stage of our renewal project by conducting excavations for the foundations of our new bioreactor. | ✅ Completed |

| 23 February 2026 | We have submitted an amendment to our development application, consisting of adjustments within the LMWQCC site such as changes to cable alignment, pipework and the earthworks profile. This amendment to DA no. 202341913 is open for public notification until Monday 16 March. | 🔄 In progress |

| 31 October 2025 | We are continuing work to prepare the site for construction of the bioreactor and supporting infrastructure. This includes relocating existing services and bulk civil works like earthworks and excavations. | 🔄 In progress |

What is a bioreactor?

A bioreactor is a critical part of the wastewater treatment process. It uses microorganisms to break down pollutants, particularly nitrogen, in wastewater. These microorganisms convert nitrogen into nitrogen gas, ensuring treated water can be safely returned to the river, helping protect the river and its ecosystem.

The bioreactor project at LMWQCC will introduce membrane bioreactor technology, which combines biological treatment with advanced membrane filtration. This will deliver high-quality treated wastewater and increase treatment capacity so we can reliably support future generations.

Community Impact

Most work will occur within the LMWQCC site, so impacts on the community will be minimal. However, over the coming months, Stockdill Drive, Drake-Brockman Drive and parts of Pro Hart Avenue will experience increased traffic from light vehicles and trucks delivering building materials, equipment, construction vehicles and machinery. The road will be regularly used by construction teams and support vehicles for site access and deliveries.

Stay updated

Interested in staying up to date with this project? Please email letstalkwater.wastewater@iconwater.com.au and we’ll keep you informed every step of the way.

Previous news

Date | Snapshot | Status |

| 20 February 2026 | A surface miner will be delivered to Lower Molonglo Water Quality Control Centre on 24 February. This may cause some traffic disruptions. Please follow all signs and directions. | ✅ Completed |

| 16 December 2025 | We’re getting ready for the next stage of the bioreactor project at Lower Molonglo Water Quality Control Centre. In early 2026, a surface miner will arrive to start excavation for the new bioreactor. Because of its size, the delivery will occur at night under regulatory approval and may cause short-term traffic changes. We’ll share more details in January once the delivery date has been finalised. | ✅ Completed |

| 1 October 2025 | We provided a project update via letterbox drop to residents of Holt, Higgins, and Strathnairn, who may be impacted by altered traffic conditions. | ✅ Completed |

| 8 September 2025 | We received approval from the ACT Government’s City and Environment Directorate for our development application amendment (DA no. 202341913). | ✅ Completed |

What will it look like once we’re done

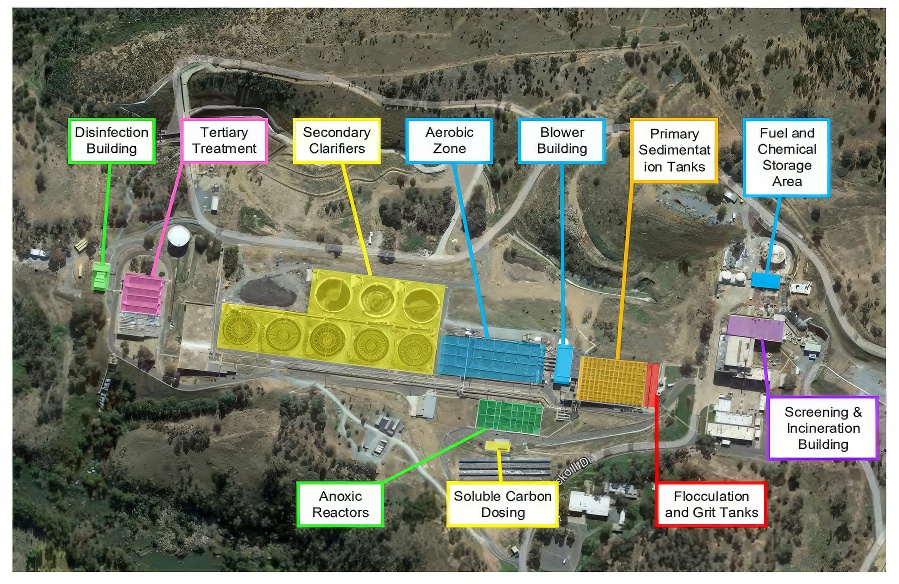

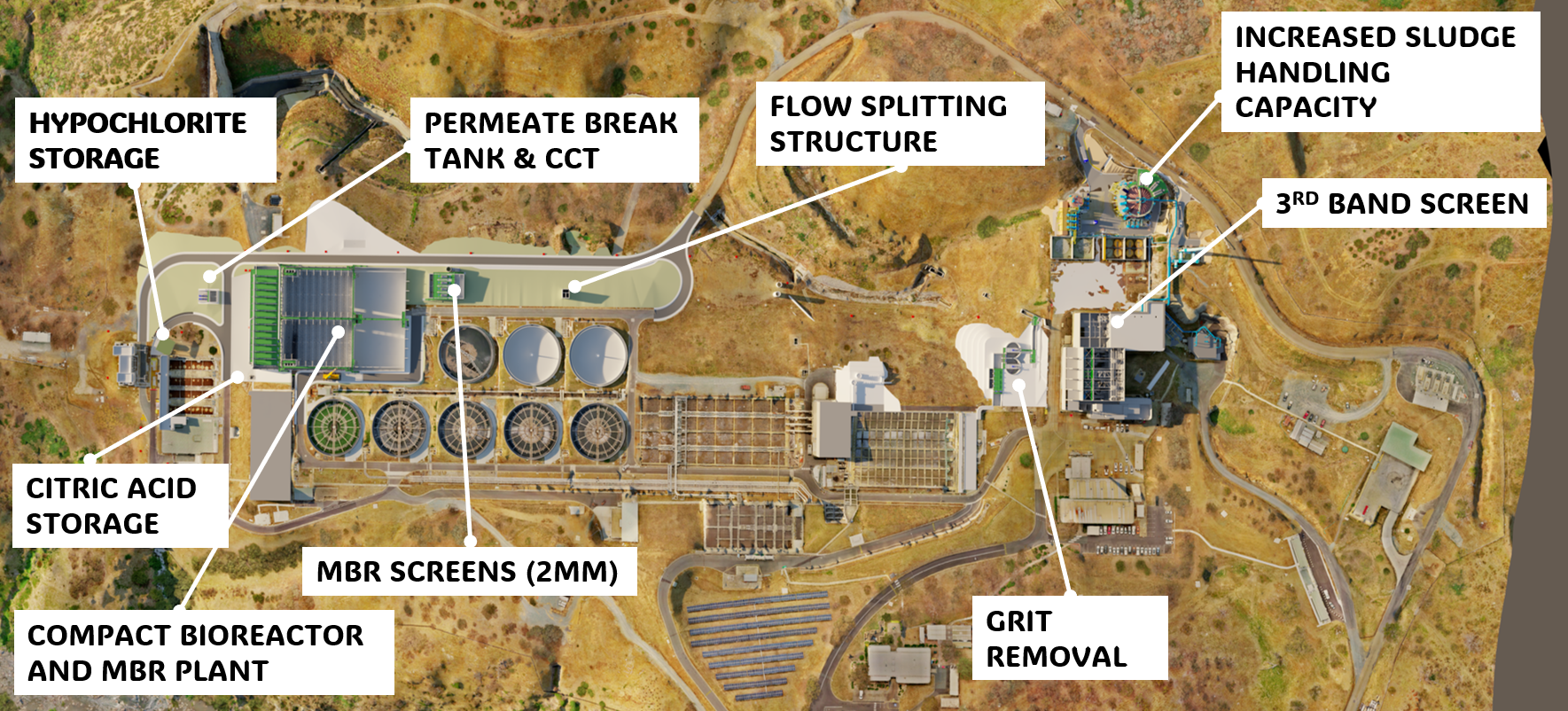

The images below can give you an idea of how our bioreactor project might change the layout at LMWQCC. The image on your left shows our facility as it currently exists, and the one on your right shows how it might look once the bioreactor is complete.

Existing layout - Click to view enlarged image |

Proposed new layout - Click to view enlarged image |

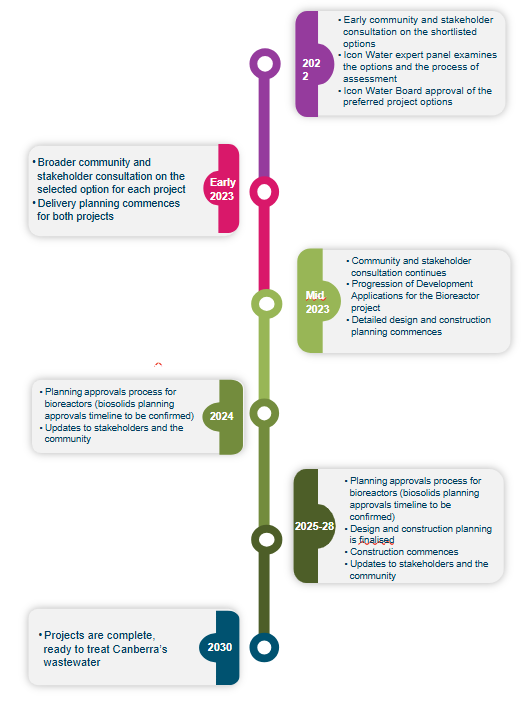

Full project timeline

FAQs

What is a bioreactor?

Our bioreactor is a key part of the wastewater treatment process at Lower Molonglo Water Quality Control Centre.

It uses natural microorganisms to remove pollutants like nitrogen from wastewater, ensuring treated water can be safely returned to the Molonglo River.

Why is Icon Water upgrading the bioreactor?

Canberra’s population is growing, and our current system is nearing capacity.

This upgrade will increase our treatment capacity which will help us meet future demand and continue to protect the environment.

What is changing as part of the upgrade?

We’re introducing advanced membrane bioreactor technology.

This technology combines biological treatment with membrane filtration to deliver high-quality treated water, reduce environmental impact, and improve efficiency.

Will there be any disruptions during the project?

Most work will happen within the LMWQCC site, so impacts on the community will be minimal.

If any changes affect services, we’ll communicate it in advance.

When will the project be completed?

The bioreactor upgrade is being delivered over several years. We’ll share key milestones and updates on our website and through community channels.

If you’re interested in staying up to date with this project, please email letstalkwater.wastewater@iconwater.com.au and we’ll keep you informed every step of the way.

How was the solution selected?

We assessed nine options, identifying the risks and benefits for each. From these, we created a shortlist:

- Option 1: Convert our existing bioreactors into a membrane bioreactor

A membrane bioreactor combines membrane filtration with a biological treatment process. - Option 2: Duplicate the existing process (with updated technology)

For this option, we would construct additional process trains but integrate similar but newer technology. - Option 3: Aerobic Granular Sludge (Nereda ®)

This process treats wastewater by creating compact sludge granules. - Option 4: Integrated Fixed Film Activated Sludge (IFAS)

The IFAS system consists of tanks filled with small pieces of plastic that create a habitat for microorganisms to attach and grow.

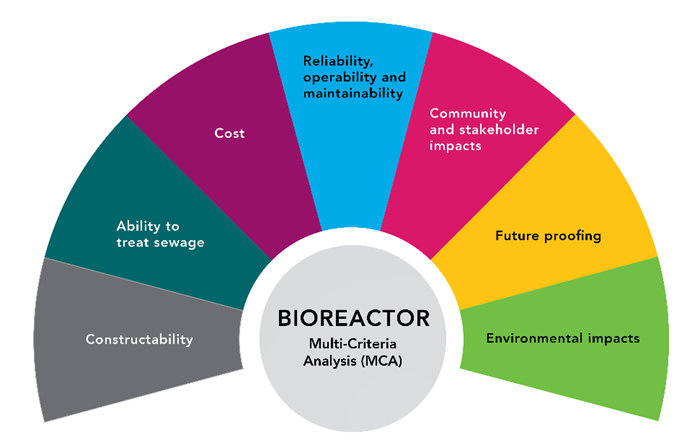

Options assessment:

These options went through a robust multi-criteria analysis to make sure we choose the solution that best factored in cost, the needs of our growing community, our environment, and our ability to treat wastewater to a high standard.

The options were assessed the options against the following criteria:

- Treatment process reliability, operability and maintainability.

- Environmental impacts.

- Community impacts.

- Constructability and flexibility to adapt to future challenges.

- Value for money for Icon Water’s customers (to find out how we fund these projects, see our factsheet on infrastructure funding).

- Ability to fit into the existing site.

After rigorous assessment of suitable technologies, we chose membrane bioreactors.

We’re always happy to help

For general enquiries, you can contact us directly at talktous@iconwater.com.au. Our team will do their best to respond within 24 hours.

If you need a bit more assistance, or just prefer talking to a person,

you can call us on (02) 6248 3111 (select option 3).